Autodesk® Moldflow® is a plastic injection analysis software used to simulate the injection process, detect potential manufacturing defects in plastic parts in advance, and make necessary changes in part design, mold design, and process parameters before production to eliminate these issues.

With its patented Dual Domain™ technology, Autodesk® Moldflow® simulates the plastic injection process quickly and accurately, ensuring that potential problems in part and mold design are resolved before the manufacturing stage.

Thanks to the advanced material database, plastic part and mold designers can easily access the material information they need. With Autodesk® Moldflow®, it is possible to perform the following analyses:

Plastic Flow Analysis:

Used to simulate filling and packing processes in plastic injection and to determine optimal process parameters. With plastic flow analysis:

Finding the Optimal Gate Location

Filling Analysis

Runner Balancing

Valve Gate Analysis

With Autodesk® Moldflow® Insight, heat transfer events inside the mold during the plastic injection process can be simulated to determine the necessary process parameters for optimal mold cooling and to design cooling components. With cooling analysis:

While performing cooling analysis in Autodesk® Moldflow®, the following cooling components can be designed:

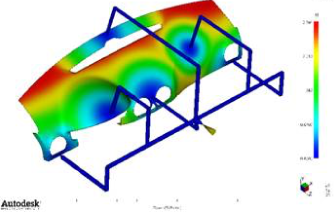

With Autodesk® Moldflow®, warpage in a plastic part can be analyzed before the part is manufactured, and the causes of the warpage can be identified and corrected. With warpage analysis:

Visualization of warpage results

Identification of factors causing warpage

During injection, the deformation of thin and long cores can be calculated, and as a result of these deformations, the thickness variations on the plastic part can be determined to check whether the design tolerances are exceeded.

With Autodesk® Moldflow®, the fiber distribution resulting from the injection of fiber-reinforced plastics can be analyzed. With fiber analysis:

Autodesk® Moldflow® material library includes a variety of additives for reinforced plastics, such as:

The thermo-mechanical properties obtained from the analysis can be exported to other structural analysis programs (ANSYS, ABAQUS).

The deformation of a plastic part and the stresses that occur under applied mechanical and thermal loads can be calculated. The analysis uses the distribution of mechanical properties obtained from the plastic injection process, enabling more realistic results. The types of analysis that can be performed include:

Using the values obtained from filling and packing analysis, the shrinkage distribution on the plastic part is calculated. With shrinkage analysis: